products

Performance Charts

- TL 10 Pressure

- TL 10 Vacuum

- TL 20 Pressure

- TL 20 Vacuum

- TL 30 Pressure

- TL 30 Vacuum

- TL 40 Pressure

- TL 40 Vacuum

- TL 41 Pressure

- TL 41 Vacuum

- TL 50 Pressure

- TL 50 Vacuum

- TL 60 Pressure

- TL 60 Vacuum

- TL 61 Pressure

- TL 61 Vacuum

- TL 70 Pressure

- TL 70 Vacuum

- TL 80 Pressure

- TL 80 Vacuum

- TL 81 Pressure

- TL 81 Vacuum

- TL 90 Pressure

- TL 90 Vacuum

- TL 100 Pressure

- TL 100 Vacuum

- TL 101 Pressure

- TL 101 Vacuum

- TL 110 Pressure

- TL 110 Vacuum

- TL 120 Pressure

- TL 120 Vacuum

- TL 600 Pressure

- TL 900 Pressure

we're here to help.

let us know how!

let us know how!

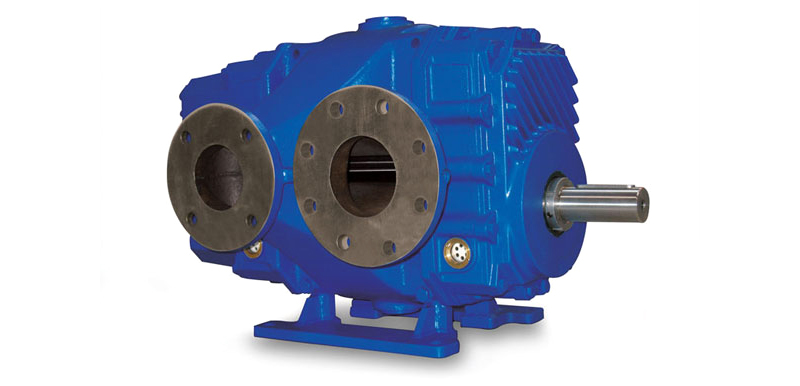

Efficiency, long life, less wear-and-tear, and versatility doesn’t happen by accident. It’s the result of smart design, and technology working together to create a quieter, smoother-running unit with capacity up to 4710 ICFM, and vacuum to 25” HG.

Key Features of our High Vacuum Exhausters:

- Bearings: Spherical/cylindrical roller and ball bearing combinations; minimum 100,000 hour design life.

- Tri-Lobe Rotors: Involute contoured impeller profiles for maximum efficiency.

- Impeller/Shaft Rigidity: Reduces mechanical deflection and vibration.

- Oil Seals: Simple non-wearing slinger type oil seals, provide positive sealing in both oil sumps. Unaffected by high temperatures. No shaft wear.

- Air Seals: Piston ring air seals provide dependable non-wearing operation to minimize air leakage past the shafts.

- Heavy-Duty and ribbed cast iron housing and end covers: Reduce noise levels and increase heat dissipation.

- Versatile Mounting: Horizontal or vertical airflow is easily achieved by relocating the removable mounting feet incorporated in all models.

- Splash Oil Lubrication: Assures improved bearing life and operational simplicity.

- Gas or air is delivered in an uncontaminated, oil free state.

- The unit may be coupled directly or driven by V-belts.

- Rotation of the impellers is synchronized by a pair of timing gears having helical, hardened and ground teeth.

- Stationary and truck mounted portable units

Note: performance data based on sea level barometer and 68F inlet temperature

Performance Charts

- TL 10 Pressure

- TL 10 Vacuum

- TL 20 Pressure

- TL 20 Vacuum

- TL 30 Pressure

- TL 30 Vacuum

- TL 40 Pressure

- TL 40 Vacuum

- TL 41 Pressure

- TL 41 Vacuum

- TL 50 Pressure

- TL 50 Vacuum

- TL 60 Pressure

- TL 60 Vacuum

- TL 61 Pressure

- TL 61 Vacuum

- TL 70 Pressure

- TL 70 Vacuum

- TL 80 Pressure

- TL 80 Vacuum

- TL 81 Pressure

- TL 81 Vacuum

- TL 90 Pressure

- TL 90 Vacuum

- TL 100 Pressure

- TL 100 Vacuum

- TL 101 Pressure

- TL 101 Vacuum

- TL 110 Pressure

- TL 110 Vacuum

- TL 120 Pressure

- TL 120 Vacuum

- TL 600 Pressure

- TL 900 Pressure

we're here to help.

let us know how!

let us know how!

1.844.898.1980

1.844.898.1980 email

email