Performance Charts

- TL 10 Pressure

- TL 10 Vacuum

- TL 20 Pressure

- TL 20 Vacuum

- TL 30 Pressure

- TL 30 Vacuum

- TL 40 Pressure

- TL 40 Vacuum

- TL 41 Pressure

- TL 41 Vacuum

- TL 50 Pressure

- TL 50 Vacuum

- TL 60 Pressure

- TL 60 Vacuum

- TL 61 Pressure

- TL 61 Vacuum

- TL 70 Pressure

- TL 70 Vacuum

- TL 80 Pressure

- TL 80 Vacuum

- TL 81 Pressure

- TL 81 Vacuum

- TL 90 Pressure

- TL 90 Vacuum

- TL 100 Pressure

- TL 100 Vacuum

- TL 101 Pressure

- TL 101 Vacuum

- TL 110 Pressure

- TL 110 Vacuum

- TL 120 Pressure

- TL 120 Vacuum

- TL 600 Pressure

- TL 900 Pressure

let us know how!

Our Tri-Lobe blowers run quieter and smoother, with less pulsation as opposed to twolobed blowers, which place a greater load and stress on the bearings and gears, thus reducing overall life. Last but not least, they will reduce your electricity bill.

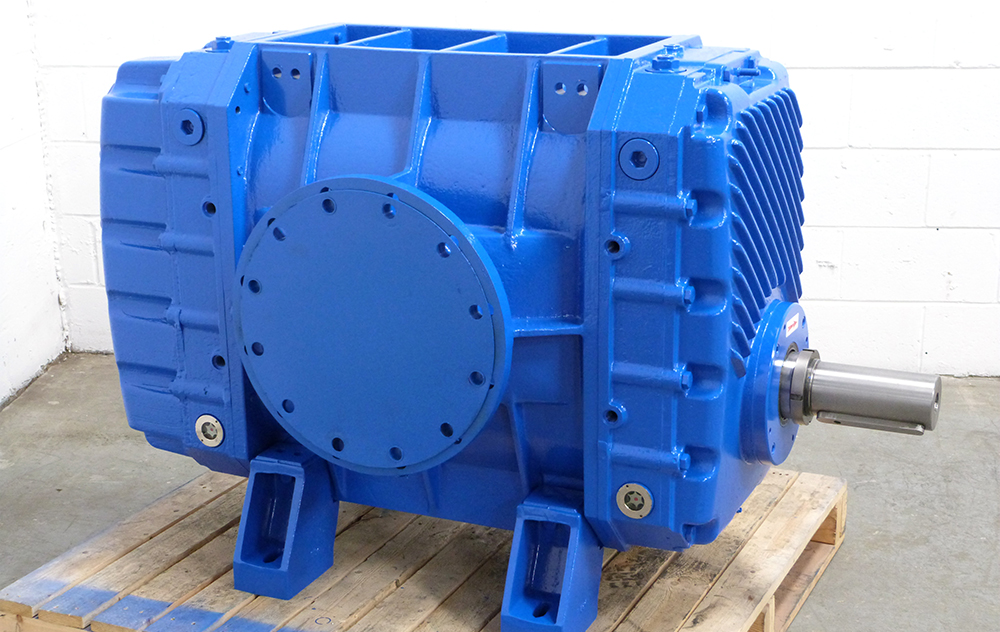

When your product is blowers and only blowers, you better build them a cut above all others. Our trademark Tri-Lobe Blowers are built better starting from the innovative design that truly guarantees they will perform better in your plant, work with every application, and contribute to the smooth operation of your business. Our customer focus places you at the centre of our operation, and drives our commitment to use the highest quality materials and designs using the latest innovations in the industry.

The Tri-Lobe Rotor Design

The Tri-Lobe rotor tips are interposed at 120 degrees around the rotor instead of 180 degrees in a two-lobe. Tri-Lobe rotors employ a six trapped pocket, which allows for a much more gradual pressure equalization than two lobes. This produces a much softer compression process, dramatically reducing shock and vibration to the blower and the whole system. The bearings and gears are also loaded more evenly, and peak loads are drastically reduced. Involute contoured impeller profiles and shaft rigidity reduce mechanical deflection and vibration. The spherical/cylindrical rollers and ball bearings combinations offer a minimum of 100,000 hour design life.

Tri-Lobe blowers have non-contacting air and oil seals. Under hot operating conditions, rubber hardens, lip-type seals wear out, and you have leakage. With our seals, no matter how hot it gets, the seal will never wear out.

Materials

On smaller units, the the rotors and impellers are made of the highest-quality steel. In the larger units, the models TL90-900, the rotors are made of fine gray cast iron and the shafts are AISI 1045 steel.

Larger Shafts and Bearings

On models TL10-81, the rotor and shaft are machined from one piece of steel which allows for a larger shaft diameter, compared to most. Rotating elements in our Tri-Lobe Blowers are stressed to a lower value of design capability. This gives you longer blower life.

No Shaft Wear and Tear

Air and oil seals of the ‘non-contact’ type are impervious to high temperatures. Multipiston rings provide a multiple labyrinth air seal which maximizes air retention in the cylinder and minimized leakage. Thus, no grinding, chroming and re-grinding of the seal location prior to the seal replacement.

Helical Gears

The rotation of the impellers is synchronized by a pair of timing gears with helical, hardened and ground teeth. All timing gears are made of alloy steel. These tooth forms have three or more teeth in continuous mesh which allows for a much smoother power flow from one rotor to the other. This results in a smoother, quieter and longer life.

Reliable Splash Lubrication

Improved bearing life. Simple, dependable splash lubrication of all gears and bearings by way of large oil reservoirs on both ends of the blower (no grease lube employed). Oil seals are non-contact and provide a non-wearing positive sealing in both oil sumps, unaffected by high temperatures.

Sanitary Air Flow

Gas and air pneumatic conveying delivered in a 100% uncontaminated oil-free state. All internal bearing oil seals are of the centrifugal slinger type which protects against shaft damage, leaks and contamination as opposed to the lip type oil seals which are a major cause of oil leaks through shaft and seal wear.

‘Low Pulse’ Control Means Less Noise

All models of our Tri-Lobe Blowers have pulse-control channels which are designed to allow the pressure in the trapped pocket to be brought to discharge pressure more gradually through a longer period of rotation. This limits pulsation and pressure fluctuation which minimizes noise generation. Heavy-duty, ribbed cast iron housing and end covers also help with noise reduction.

Performance Charts

- TL 10 Pressure

- TL 10 Vacuum

- TL 20 Pressure

- TL 20 Vacuum

- TL 30 Pressure

- TL 30 Vacuum

- TL 40 Pressure

- TL 40 Vacuum

- TL 41 Pressure

- TL 41 Vacuum

- TL 50 Pressure

- TL 50 Vacuum

- TL 60 Pressure

- TL 60 Vacuum

- TL 61 Pressure

- TL 61 Vacuum

- TL 70 Pressure

- TL 70 Vacuum

- TL 80 Pressure

- TL 80 Vacuum

- TL 81 Pressure

- TL 81 Vacuum

- TL 90 Pressure

- TL 90 Vacuum

- TL 100 Pressure

- TL 100 Vacuum

- TL 101 Pressure

- TL 101 Vacuum

- TL 110 Pressure

- TL 110 Vacuum

- TL 120 Pressure

- TL 120 Vacuum

- TL 600 Pressure

- TL 900 Pressure

let us know how!

1.844.898.1980

1.844.898.1980 email

email